Our Equipment

Precision from

Start to Finish

With some of the best programmers in Utah and state-of-the-art equipment at our disposal, Lindon Precision is a large-scale manufacturing partner you can count on from start to finish for all your machining needs.

CNC Capabilities

Lindon Precision at a Glance

Our fully loaded production floor boasts 14 CNC machines that allow us to craft precision components around the clock. Since 2022, we’ve invested millions of dollars in equipment to help get you to market quicker than ever, with parts perfectly machined to your exact specifications.

-

With our top-of-the-line equipment and automation at every step, we’re primed and ready to tackle medium- and large-scale production volumes.

-

No project is too complex. With our expert engineering team and state-of-the-art equipment, we guarantee each component will meet exact specifications - big or small.

-

Our state-of-the-art equipment allows for larger X, Y, and Z machining dimensions than ever before.

-

We’ve streamlined production with the latest tech and our team of engineers. Often, parts can be completed in a single operation, and we pass the savings on to you!

-

Production at Lindon Precision happens around the clock, meaning quicker turnaround times and stocked shelves for your business. No surprises; we guarantee an exact delivery date for each project.

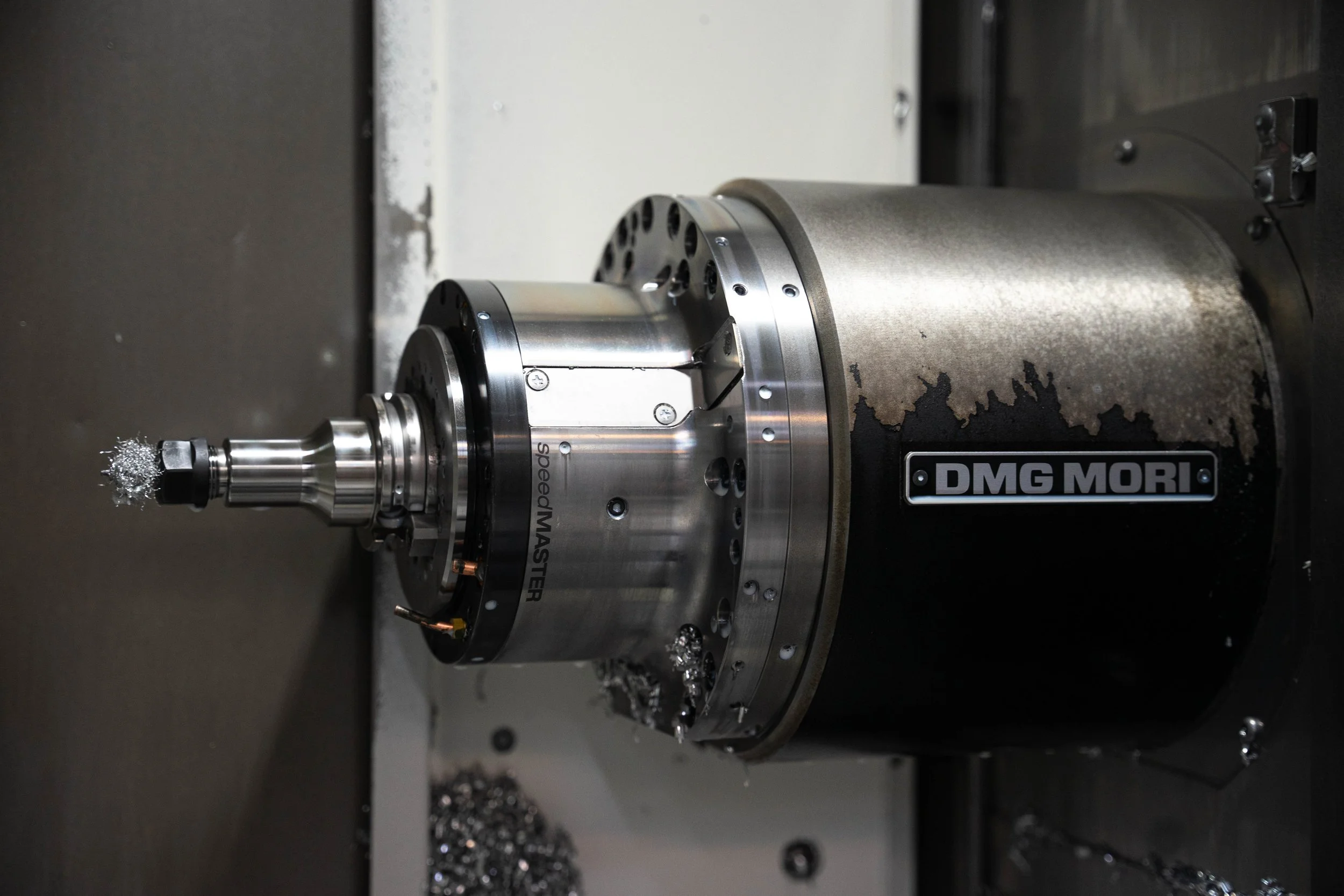

Equipment Highlight #1

DMG MORI NTX1000

New to our lineup in June 2024 is the DMG MORI NTX1000, a 9-axis, mill-turn lathe offering lights-out machining and 5-axis capabilities. There's a lot to love about this machine, including a 20,000rpm spindle, a 76-piece tool belt, and an incredible 240-degree B-axis range. This production beast is one of our flagship pieces of equipment, increasing our capacity by more than 15%.

Travel Specs:

X Travel 17.9'‘

Y Travel 8.3'‘

Z Travel 31.5”

Max workpiece diameter: 16.9“

Max workpiece length: 31.5”

-

In a 5-axis machine, cutting tools can move across five axes simultaneously: X, Y, Z, A, and B (i.e., parts can be cut along the X-axis, Y-axis, and vertically while also allowing for rotational cuts on an additional two axes.) This allows for machining complex geometries and angles in one go. This is particularly useful for parts with intricate contours, undercuts, or other features that require a high level of detail while not sacrificing precision or turnaround times.

-

The B-axis represents the rotational axis in machining, in other words, circular rotation around the workpiece.

-

The NTX1000 allows us to change tools on the fly, meaning less downtime, more complex machining options for you, and next-level consistency in each machined part.

-

Two hundred forty degrees of B-axis travel allows us to cut incredibly complex parts, often in a single operation. This means quicker production times, less finishing work, and beautifully machined parts every time.

-

We're constantly updating our arsenal with state-of-the-art equipment to serve you better! As we bring new tech in, our expert team of machinists and engineers can provide tighter tolerances, quicker turnaround times, and cost savings that we pass onto you for each of your production runs. With the addition of the NTX1000 alone, we anticipate a 15-20% increase in production capacity. Want to see what Lindon Precision can do for your next production cycle? Contact us today!

Equipment Highlight #2

DMG MORI NHX5000

-

X travel 28.7”

Y Travel 28.7”

Z Travel 34.6”

A large-scale production workhorse with large travel allowing for large format parts with tight tolerances

The NHX5000 offers 4th-axis capabilities, allowing the device to rotate while cutting. This enables us to machine intricate shapes and contours while permitting one continuous cut. This machine also features a 20K rpm spindle for lightning-fast machining.

-

All of our DMG Mori machines are very versatile and allow us to eliminate multiple setups, saving you time and money. Often, these machines complete the part in a single operation.

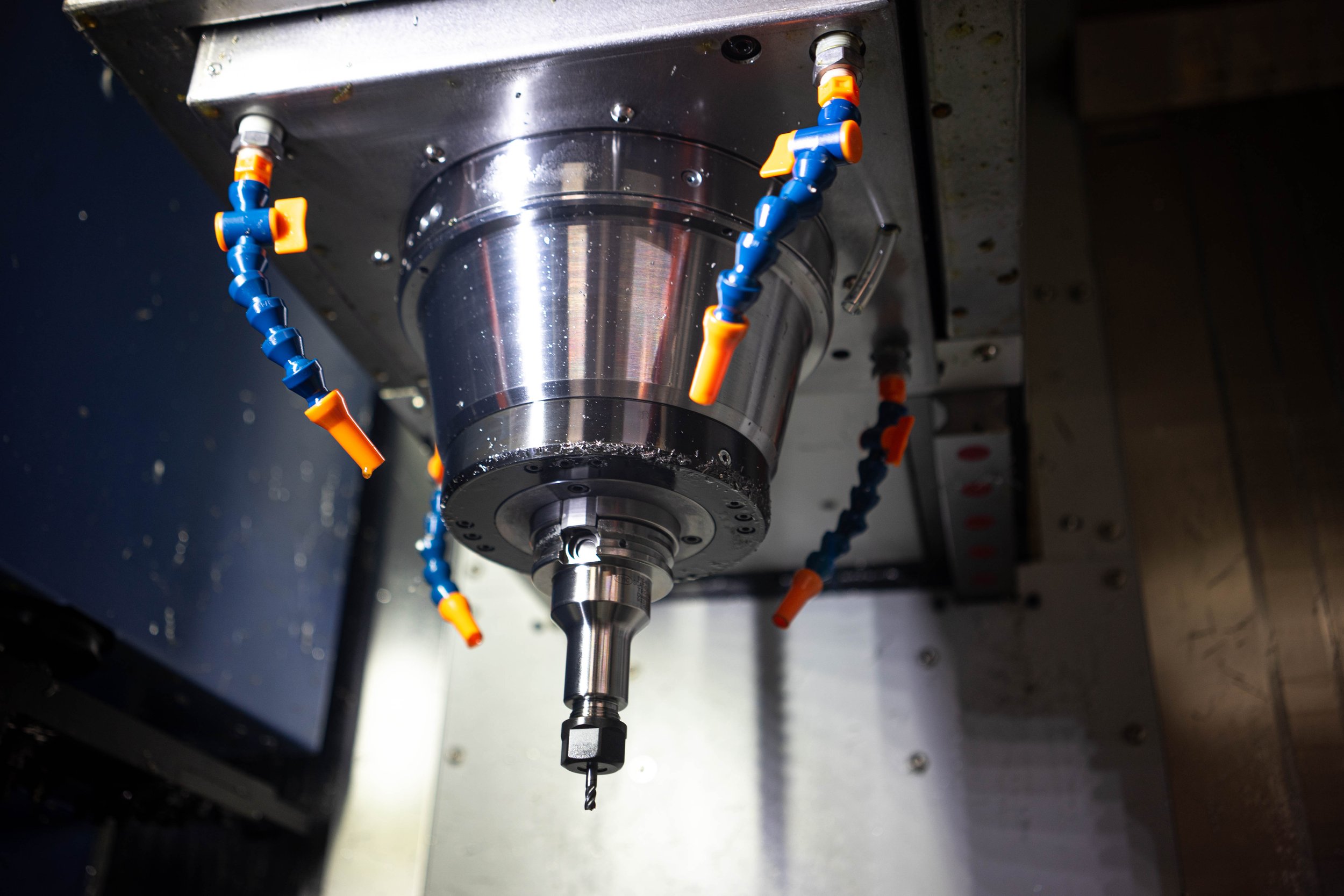

Equipment Highlight #3

DMG MORI NHX4000 with RPP (Rotating Pallet Pool)

The second DMG MORI machine we’re featuring is the NHX4000, a lights-out piece of equipment with five pallets available to set up multiple jobs. Lights out isn’t just a superlative; it means we can set up numerous projects in advance, making it possible to run the NHX4000 unattended for extended periods, even overnight. With this level of automation, we can maintain next-level precision and control along with 24/7 production cycles.

-

1) Reduced Setup Time

In traditional machines, significant time is often lost while machines are idle during setup for different parts. With a rotating pallet pool, setups can be done offline on spare pallets while the machine is still running a different job.

2) Continuous Production:

With a rotating pallet pool, CNC machines can keep running almost non-stop. As one job completes, another pre-set pallet can be automatically loaded into the machine. This allows “lights out” production so parts can continue being cut even when the office is empty.

3) Flexibility in Scheduling:

Having multiple pallets prepped with different setups allows for greater flexibility in production scheduling. If you have a change in needs, we can quickly shift focus to get your production cycle on track.

Like the other DMG MORI machines in our arsenal, the NHX4000 features full 4th-axis capabilities with a 20K rpm Spindle, allowing us to machine intricate designs, often in a single operation.

Equipment Highlight #4

DN Solutions DVF5000

This machine is seriously impressive. It offers true 5-axis capabilities with eight pallets set up to rotate in different jobs on the fly.

Travel Specs:

X travel 24.6” Y Travel 17.7” Z Travel 15.7”

-

In a 5-axis machine, cutting tools can move across five axes simultaneously: X, Y, Z, A, and B (i.e., parts can be cut along the X-axis, Y-axis, and vertically while also allowing for rotational cuts on an additional two axes.) This allows for machining complex geometries and angles in one go. This is particularly useful for parts with intricate contours, undercuts, or other features that require a high level of detail while not sacrificing precision or turnaround times.

-

With 5-axis machining technology, you can create complex geometries such as twisted shapes, sculpted surfaces, and intricate contours. The technology allows cutting tools to access hard-to-reach areas from multiple angles, and it allows for the creation of undercuts and intersecting features that would be impossible to achieve with traditional 3-axis machines. Even if your part doesn't include complex geometry, this technology allows parts to be completed in a single operation, reducing setup times, overall costs, and turnaround times.

This vertical mill is another standout in our collection of DMG Mori machines. It features a 15K rpm spindle with full milling and four-axis capabilities.

We utilize numerous DMG MORI machines on our production floor because of their rock-solid performance, precision, and dependability. They allow us to produce precision parts without multiple setups, saving you time & money.

Equipment Highlight #5

DMG MORI CMX 1100V

with DDRT

Equipment Highlight #6

DMG MORI

NLX2500 & NLX1500

(3x) DMG MORI NLX2500 + (1x) DMG MORI NLX1500

An additional three DMG MORI NLX2500s and a DMG MORI NLX1500 round out our collection of DMG MORI machines. Like the others, they are twin spindle production powerhouses with 4-axis capabilities.

With all of this equipment, we can produce most parts in one operation, meaning lightning-fast turnaround times and less cost impact on your bottom line.

Additional Equipment

Twin Spindle, Twin Turret

Miyano Citizen Lathe

The Miyano Citizen is a twin spindle/twin turret that is built for production. It has all the versatility of the NLX’s but with an added turret so it can be machining in two locations at the same time.

Bonus Production Volume

Fadal Vertical

Machining Centers (4x)

These tried and true vertical machines give us rock-solid precision and added production volume.

Our shop features four of these vertical mills, each with travel specifications of:

X travel 45” - Y Travel 25” - Z Travel 35”

Get Started Today

The Right Tools

for Any Job

Whatever your industry and project scale, Lindon Precision has the outstanding combination of expertise and top-of-the-line equipment to swiftly take your project from concept to market.