Coordinate Measuring Machine Services

Premier CMM Services in Utah

At Lindon Precision, we offer all-inclusive CMM (coordinate measuring machine) services, including Geometric Dimensioning and Tolerancing, full specification printouts, razor-sharp accuracy, and tolerances within 10ths of thousandths of an inch (.0005 inches). Whether you are developing a new product, bringing back a staple, or looking to onboard with a new machine shop, you can trust our team to provide exceptional precision and customer service from start to finish.

CMM with Lindon Precision

Precision You Can Count On

Using top-of-the-line CMM and reverse engineering equipment, we can bring your project to life whether you are still in the prototyping stage or gearing up for a full production run.

Work in tandem with our team through GD&T, prototyping, and onboarding, and experience the white-glove customer service that has kept us in business since 1975.

-

We live up to our name at Lindon Precision by providing highly accurate measurements with tolerances as tight as .0005 inches.

-

From tiny medical components to large format automotive and aerospace components, Lindon Precision can tackle all of your CMM challenges big and small.

-

We understand the challenge of needing parts yesterday. From quoting and onboarding to delivery, count on quick turnaround times and guaranteed delivery dates.

-

After meeting your CMM needs, our team is standing by to provide 24/7 production cycles in our full-service machine shop. If you're still in the prototyping stage, our engineers can work with you step by step throughout product development. Have other production or finishing needs? Our team has resources and connections to help you get your project across the finish line, whatever your requirements.

-

Since 1975, we've built a reputation as Utah's finest machine shop by offering exceptional customer service and quality machining solutions. At Lindon Precision, you can expect clear communication, kept promises, and a team that goes above and beyond from start to finish.

CMM with Lindon Precision

How it Works

01

Get in Touch

Submit your project online, via email, over the phone, or in-person at our shop in Lindon. We’ll be in touch within 24-hours.

Onboarding

Ship or drop off your part in person. Our engineering team will chat with you to learn your project specifics, tolerances, and everything we need to get started.

02

Scan, Create a Package, Send Results

Using our top-of-the-line equipment, we’ll scan your part and prepare a package of your part's full specifications and 3D models. We’ll send the results and get in touch to discuss next steps.

03

Next Steps/ Production

Whether you are ready for a full production run, want to prepare prototypes, or anything else, Lindon Precision’s team will work hand-in-hand with you to get your project across the finish line.

04

CMM 101

CMM FAQs

Want to learn a bit more about CMM and our services? Here are some of our most frequently asked questions.

-

CMM stands for Coordinate Measuring Machine. Simply put CMM allows us to use technology to accurately map specifications, geometry, and tolerances for a physical object.

-

Accurate coordinate measuring is essential in product development, QC, inspection, reverse engineering and more.

Product Development: Utilize CMM to get accurate measurements for your components and specialized tolerances for your parts. Say goodbye to inconsistencies from component to component.

QC: With upfront CMM work, you can count on laser-accurate 3D models to produce your parts. Following a production cycle, you can utilize CMM software to ensure parts are up to your quality standard.

Reverse Engineering: Do you have a part or prototype in hand without 3D models? No problem! Utilizing CMM, engineers can reverse engineer an existing component and obtain highly detailed 3D models to further develop or reproduce the project. -

Our equipment and engineers allow us to offer tolerances to the tenths of thousandths of inches (.0005 inches).

-

We try to respond to any customer contact within 24 hours. Typically our project turnaround times are 2-3 weeks depending on the scope of your project.

We also offer rush delivery options, Contact Us for details.

A Look Under the Hood

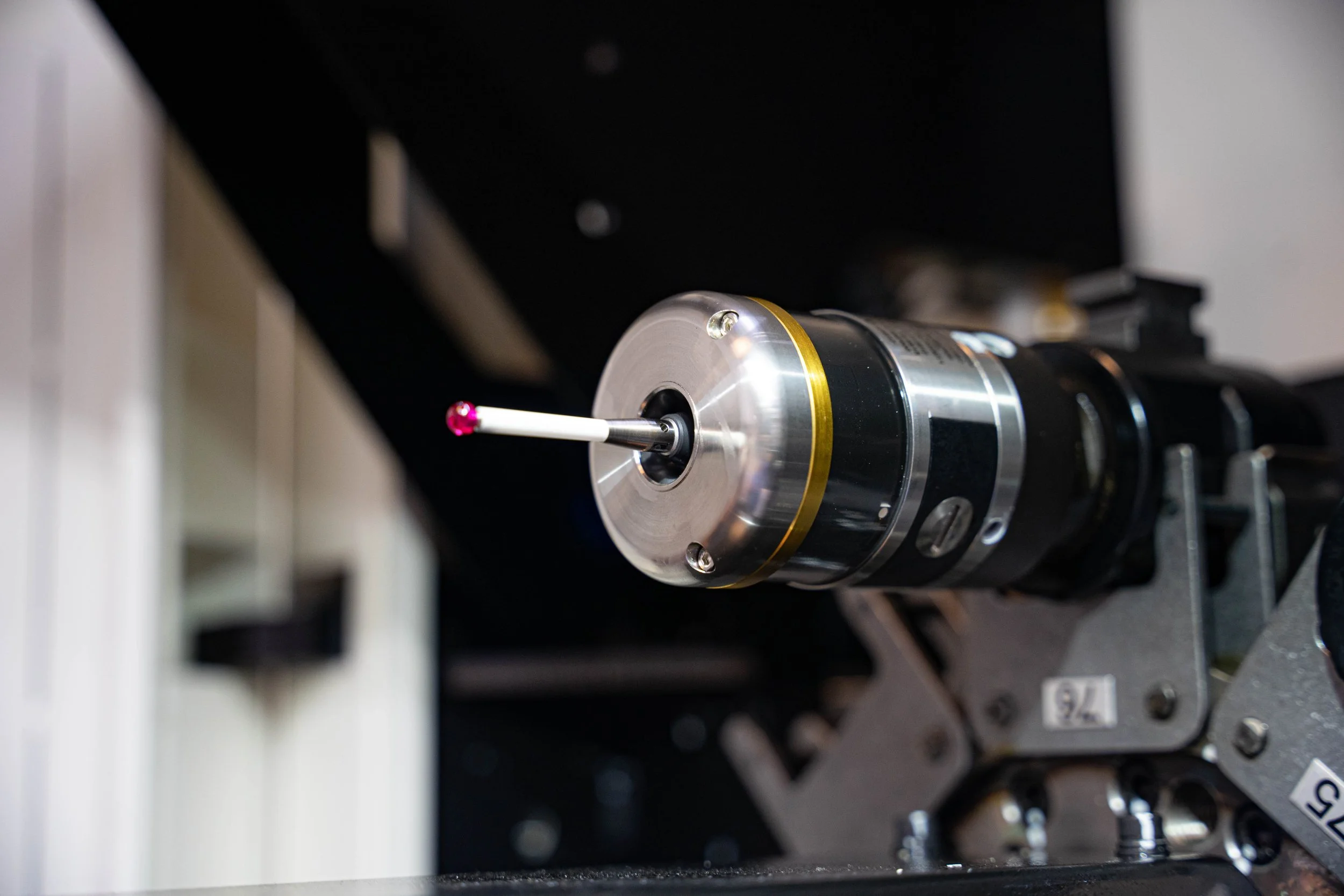

Top Tier CMM Equipment & Software

We’ve heavily invested in the latest and greatest in CMM technology. Our Keyence VL Series machine lets us go from scans to STEP files in one simple operation, saving you time and money while providing insane precision. When paired with our engineering team, you can count on exceptional renderings and tolerances within .0005 inches.

-

Our Keyence machine allows us to scan objects roughly 20" x 20" x 8".

Once scanned, your resultant file package will offer a seamless, precise render for future production runs. Our engineers can handle even the most complex designs, including sloped overhangs, thin walls, complex geometry, cavitations, and more.

We love a design challenge and are confident in our ability to get your project over the finish line wherever you are at in the manufacturing process.

The Lindon Precision Difference

Our Commitment to You

Quality Control Comes Standard

With our expert team and state-of-the-art equipment, you can always count on perfect measurements for all of your upcoming projects.

01

Exceptional Customer Service

We’ll go the extra mile to earn and keep your business. Let us know how we can help meet your production goals from quoting to delivery.

02

Guaranteed Delivery Dates

Every CMM Project begins by setting a guaranteed delivery date with our customers. Get your measurements, files, and parts right when you need them.

03

Don’t Delay

Get Started Today

Contact our team of experts and get a customized quote in as little as 24 hours. If you have proprietary designs or other Intellectual Property concerns, no worries! Use the link below to submit your NDA. We’ll return a signed copy to you and be in touch ASAP.